Introduction: The Unexpected Vertical Harvest

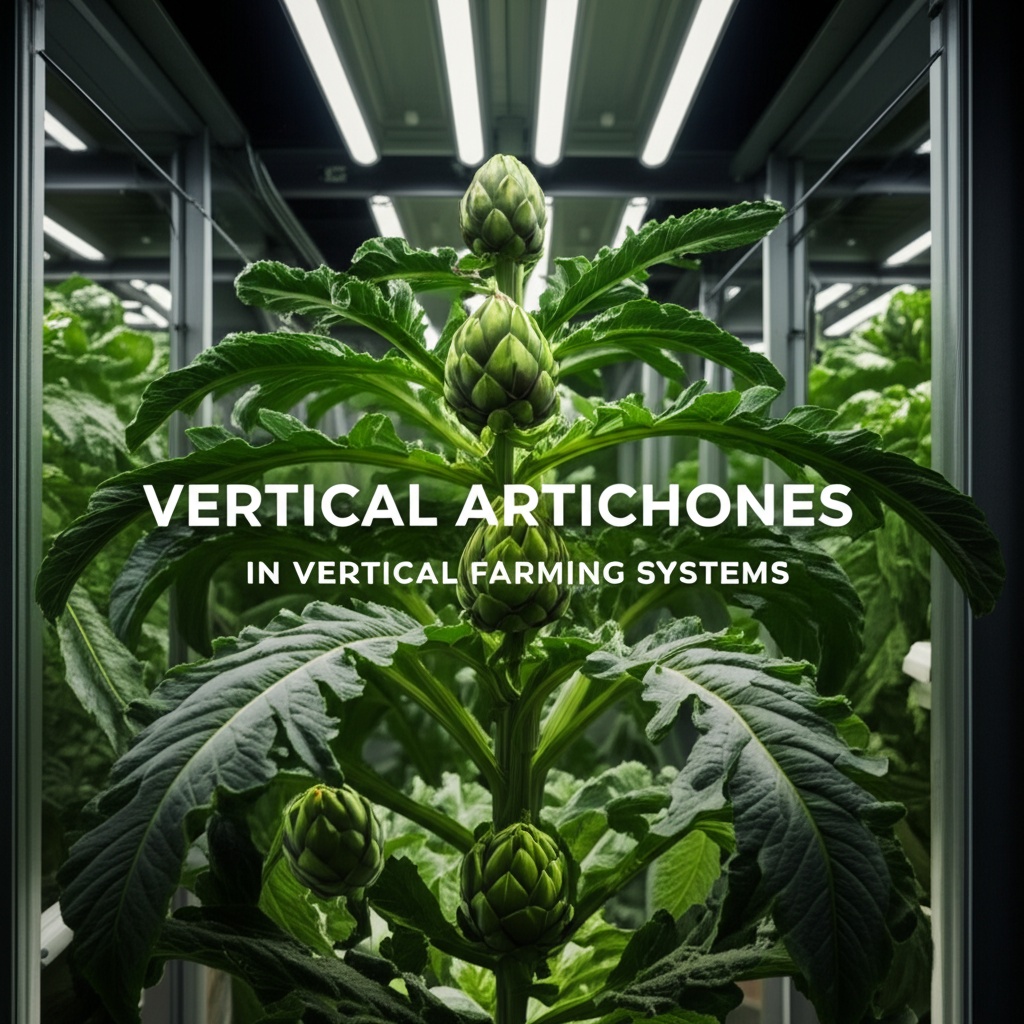

Vertical farming, once primarily associated with leafy greens and herbs, is increasingly demonstrating its potential for a wider array of crops. Among the more surprising contenders is the globe artichoke (Cynara cardunculus var. scolymus), a thistle-like plant cherished for its edible flower buds. Traditionally grown in temperate climates with ample space, the globe artichoke presents a unique challenge and opportunity for the controlled environments of vertical farms. This article delves into the feasibility, benefits, challenges, and future prospects of cultivating globe artichokes within these innovative agricultural systems. We will explore the scientific underpinnings, practical considerations, and the potential impact on food security and culinary landscapes.

Understanding the Globe Artichoke: A Culinary Icon

Before exploring its vertical farming potential, it’s crucial to understand the globe artichoke’s unique characteristics. This perennial plant, native to the Mediterranean region, is primarily cultivated for its immature flower buds. These buds, when cooked, reveal tender, fleshy bases and leaves that are a delicacy in many cuisines.

Key Growing Requirements

Globe artichokes are known for being relatively hardy but have specific needs:

- Climate: They prefer temperate climates with mild winters and cool summers. They require a period of vernalization (cold exposure) to initiate flowering.

- Soil: Rich, well-draining soil is essential. They are heavy feeders and benefit from compost.

- Sunlight: Full sun is necessary for optimal growth and bud development.

- Space: Artichokes are large plants, often growing to 3-6 feet tall and wide, requiring significant spacing in traditional field cultivation.

- Water: Consistent moisture is important, especially during bud formation, but waterlogged roots can lead to disease.

These requirements, particularly the need for space and specific climate conditions, are precisely what vertical farming systems aim to optimize and control.

The Vertical Farming Advantage for Globe Artichokes

Vertical farming offers a controlled environment that can mitigate many of the challenges associated with traditional artichoke cultivation. By precisely managing environmental factors, vertical farms can potentially overcome space limitations and climate dependency.

Precision Environmental Control

Vertical farming excels at manipulating key environmental variables:

- Temperature: Maintaining optimal temperature ranges for each growth stage can accelerate development and improve yield. The vernalization requirement can be managed through controlled cooling periods.

- Light: Artificial lighting, typically LEDs, can be tailored to provide the specific spectrum and intensity required for artichoke growth and bud development, ensuring consistent light exposure regardless of external conditions.

- Water and Nutrients: Hydroponic or aeroponic systems deliver precise amounts of water and dissolved nutrients directly to the plant roots, optimizing uptake and minimizing waste. This is particularly beneficial for heavy feeders like artichokes.

- Humidity: Controlled humidity levels can prevent fungal diseases, a common issue with artichokes in damp conditions.

- CO2 Enrichment: Elevated CO2 levels can boost photosynthesis and plant growth.

Space Efficiency and Yield Maximization

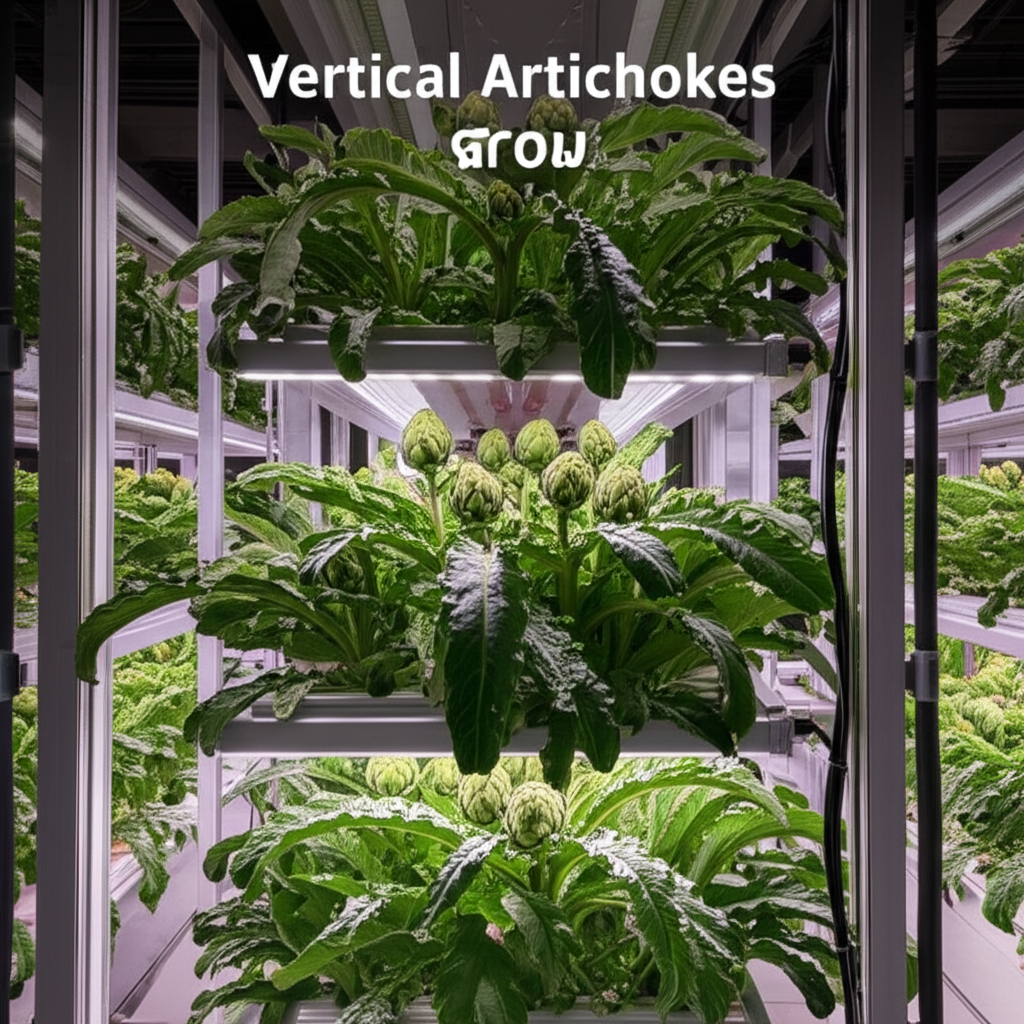

The layered structure of vertical farms allows for significantly higher plant density compared to field cultivation. While artichokes are large plants, innovative rack design and vertical stacking can maximize the use of available space. This intensified cultivation can lead to a more consistent and predictable harvest.

Reduced Environmental Impact

Vertical farming often boasts a lower environmental footprint:

- Water Conservation: Recirculating hydroponic systems use up to 95% less water than traditional agriculture.

- Reduced Pesticide Use: The controlled environment minimizes pest and diseaseIntroduction, drastically reducing or eliminating the need for chemical pesticides.

- Local Production: Growing crops closer to urban centers reduces transportation emissions and spoilage.

Key Facts and Comparison: Globe Artichokes in Vertical vs. Traditional Farming

The table below highlights the fundamental differences and potential advantages of growing globe artichokes in a vertical farming system compared to conventional field agriculture.

| Feature | Vertical Farming | Traditional Field Farming |

|---|---|---|

| Space Requirement | High density, multi-layered systems | Significant ground space, wider spacing |

| Climate Dependence | Minimal; fully controlled environment | High; requires specific temperate climates |

| Water Usage | Very low (recirculating systems) | Moderate to high (depending on irrigation) |

| Pest & Disease Risk | Very low (controlled environment) | Moderate to high; requires pest management |

| Nutrient Delivery | Precise, automated (hydroponics/aeroponics) | Soil-based, broadcast application |

| Vernalization | Controlled cooling periods | Natural winter chilling |

| Harvest Consistency | High; predictable yields | Variable; subject to weather fluctuations |

| Initial Setup Cost | High | Lower |

| Energy Consumption | High (lighting, climate control) | Lower (relies on sunlight) |

| Labor Input | Can be lower for some tasks (automation) | Can be high for planting, weeding, harvesting |

Technical Considerations for Vertical Artichoke Cultivation

While the concept is promising, several technical hurdles must be addressed for successful vertical artichoke farming. The sheer size of the mature plant and its specific physiological needs, particularly vernalization, require careful system design and management.

System Design and Infrastructure

- Vertical Racking: Artichokes require substantial vertical and horizontal space. Racking systems will need to accommodate plants that can reach heights of 3-6 feet and spread significantly. This might necessitate wider aisles or specialized racking that allows for plant expansion.

- Lighting: Artichokes are sun-loving plants. Full-spectrum LED lighting will be crucial, mimicking natural sunlight. The intensity and photoperiod will need to be carefully calibrated to promote vegetative growth and then bud initiation.

- Nutrient Delivery Systems: Hydroponic systems, such as Deep Water Culture (DWC) or Nutrient Film Technique (NFT), are viable. Aeroponics could also be explored for efficient nutrient delivery and root oxygenation. The delivery system must be robust enough to support the large root mass of mature artichoke plants.

- Climate Control: Precise control over temperature, humidity, and CO2 levels is paramount. This includes specialized cooling systems to provide the necessary vernalization period without detrimental effects on other crops in a multi-crop facility.

Cultivar Selection

Not all globe artichoke varieties are created equal. Selecting dwarf or more compact cultivars that are bred for early maturity and adaptability to controlled environments will be critical. Research into varieties that require less stringent vernalization or can initiate flowering under artificial conditions is ongoing.

Vernalization Management

The requirement for a cold period (vernalization) to trigger flowering is a significant consideration. In vertical farms, this can be achieved by:

- Dedicated Cooling Zones: Designating specific climate-controlled zones within the farm where plants are subjected to lower temperatures for a set period.

- Interrupting Growth Cycles: Moving plants to a cooler environment between growth cycles.

- Genetic Modification/Selective Breeding: Future developments might lead to artichoke varieties that require less or no vernalization.

Nutrient Management

Artichokes are heavy feeders. A nutrient solution tailored to their specific needs at different growth stages will be essential. This includes ensuring adequate levels of nitrogen, phosphorus, potassium, and micronutrients. Monitoring and adjusting the nutrient solution’s pH and electrical conductivity (EC) is critical for optimal uptake.

Steps for Implementing Vertical Globe Artichoke Cultivation

The transition from traditional farming to vertical cultivation requires a systematic approach. The following steps outline a general framework for establishing a vertical artichoke operation.

| Stage | Key Actions | Considerations |

|---|---|---|

| 1. Planning & Design | Site selection, system type (hydroponics, aeroponics), vertical rack design, lighting strategy, climate control systems, cultivar selection. | Space requirements, energy infrastructure, budget, regulatory compliance. |

| 2. Nursery & Propagation | Seed germination or transplanting from seedlings. Controlled environment for young plants. | Sterile conditions, optimal temperature/humidity for germination, appropriate lighting for seedlings. |

| 3. Transplanting & Initial Growth | Moving young plants to the vertical growing system. Initial nutrient solution and lighting. | Adequate spacing on racks, monitoring for root development, initial CO2 enrichment. |

| 4. Vegetative Growth Phase | Optimizing light, temperature, and nutrients for robust leaf and root development. | Longer photoperiods, balanced nutrient ratios, potential for controlled humidity to prevent disease. |

| 5. Vernalization Phase | Subjecting plants to a controlled period of cooler temperatures. | Precise temperature control, duration of cold period based on cultivar, potential impact on adjacent crops if not zoned. |

| 6. Bud Formation & Maturation | Adjusting lighting (potentially shorter photoperiod), nutrient composition (e.g., higher P & K), and temperature for bud development. | Monitoring bud growth and development, ensuring consistent moisture, pest/disease monitoring. |

| 7. Harvesting | Manual harvesting of mature flower buds. | Timing is crucial for optimal quality, post-harvest handling to maintain freshness. |

| 8. Post-Harvest & Processing | Cleaning, sorting, packaging, and distribution. | Maintaining cold chain, quality control, market access. |

| 9. System Maintenance & Optimization | Regular checks of pumps, lights, sensors, nutrient levels, and environmental controls. | Preventative maintenance, data logging for continuous improvement, sanitation protocols. |

Pros and Cons of Vertical Globe Artichoke Farming

Embracing vertical farming for globe artichokes comes with a distinct set of advantages and disadvantages. Understanding these is key to assessing the viability and strategic implementation of such an endeavor.

Advantages (Pros)

- Year-Round Production: Consistent supply regardless of season or external weather conditions.

- Increased Yield Density: Maximizing production in smaller footprints.

- Reduced Water Usage: Significant water savings through recirculating hydroponic systems.

- Pesticide-Free Produce: Controlled environments minimize pest and disease outbreaks.

- Improved Quality and Consistency: Uniform growth conditions lead to more predictable product quality.

- Local Production: Reduced transportation costs and emissions, fresher produce for consumers.

- Controlled Vernalization: Reliable induction of flowering through managed cold periods.

Disadvantages (Cons)

- High Initial Investment: Significant capital required for infrastructure and technology.

- High Energy Consumption: Reliance on artificial lighting and climate control systems can lead to substantial energy costs.

- Technical Expertise Required: Sophisticated knowledge of plant physiology, system operation, and data management is necessary.

- Space Limitations for Large Plants: Artichokes are naturally large plants, requiring careful rack design and potentially lower plant densities compared to smaller crops.

- Potential for System Failure: Dependence on technology means that malfunctions can lead to significant crop loss.

- Limited Cultivar Options: The range of artichoke varieties suitable for vertical farming is still developing.

The Future of Vertical Artichokes

The integration of globe artichokes into vertical farming systems represents a frontier in agricultural innovation. As technology advances and our understanding of plant physiology in controlled environments deepens, the viability of such operations is expected to grow.

Technological Advancements

- AI and Automation: Artificial intelligence can optimize nutrient delivery, lighting schedules, and climate control in real-time, further enhancing efficiency and yield. Robotic harvesting could also become a reality for these large plants.

- Genomic Selection and Breeding: Future research will likely focus on developing artichoke cultivars specifically suited for vertical farming, perhaps with reduced size, faster maturity, and less dependence on vernalization.

- Energy Efficiency: Advancements in LED lighting technology and renewable energy integration will help mitigate the high energy consumption of vertical farms.

Market Potential and Culinary Innovation

Successfully cultivating globe artichokes in vertical farms could lead to:

- Enhanced Access to Fresh Produce: Artichokes could become more readily available in urban areas where traditional cultivation is impractical.

- New Culinary Opportunities: Consistent, high-quality supply could spur innovation in restaurant menus and packaged food products.

- Reduced Supply Chain Vulnerabilities: Localized production offers a buffer against disruptions in traditional agricultural supply chains.

Conclusion: A New Leaf for the Globe Artichoke

The globe artichoke, a staple of Mediterranean cuisine and a plant of considerable stature, is finding an unlikely home in the precision-engineered environments of vertical farms. While challenges related to space, energy, and specific physiological requirements like vernalization exist, the potential benefits of year-round, sustainable, and locally grown artichokes are significant. As technology continues to evolve and our understanding of controlled environment agriculture expands, the prospect of these thistle-like delicacies thriving in stacked layers, delivering fresh produce to urban centers, appears increasingly realistic. The vertical farm is not just for salads anymore; it’s a testament to the adaptability of agriculture in meeting the demands of a changing world.